Basic Titanium Metallurgy

Commercial Titanium Alloys

September 26, 2016Why Select Titanium Alloys

September 26, 2016Basic Titanium Metallurgy

Ti-Material-Analysis

GRADE 5 (R56400) Ti-6Al-4V

GRADE 1 (R50250)

Grade2 & Grade3

GRADE 4 (R50700)

Grade7 & Grade11

Ti - 0.15Pd (Grade 16)

Ti - 0.1Ru (Grade 27)

Grade9 & Grade12

Ti - 3Al - 2.5V - 0.05Pd

Grade6 & Grade28

Ti - 5Al - 2.5Sn - ELI

Ti-8Al-1Mo-1V & Ti-6Al-2Sn-4Zr-2Mo-0.1Si

Grade23 & Grade29

Ti - 6Al - 6V - 2Sn

Ti-6Al-2Sn-4Zr-6Mo & Ti-6Al-2Sn-2Zr-2Mo-2Cr-0.1

Ti - 5Al - 2Zr - 2Sn - 4Mo - 4Cr

Ti-4.5Al-3V-2Mo-2Fe & Ti-4Al-4Mo-2Sn-0.5Si

Ti - 10V - 2Fe - 3Al

Grade19; Grade20

Basic Titanium Metallurgy

USTi mill products are available in both commercially pure and alloy grades and can be grouped into three categories according to the predominant phase or phases in their microstructure: alpha, alpha-beta, and beta. Although each of these three general alloy types requires specific and different mill processing methodologies, each offers a unique set of properties that may be advantageous for a given application. In pure titanium, the alpha phase is characterized by a hexagonal close packed crystalline structure. It is stable from room temperature to approximately 882°C (1620°F). The beta phase in pure titanium has a body-centered cubic structure and is stable from approximately 882°C (1620°F) to the melting point of about 1688°C (3040°F).Effects of Alloying Elements

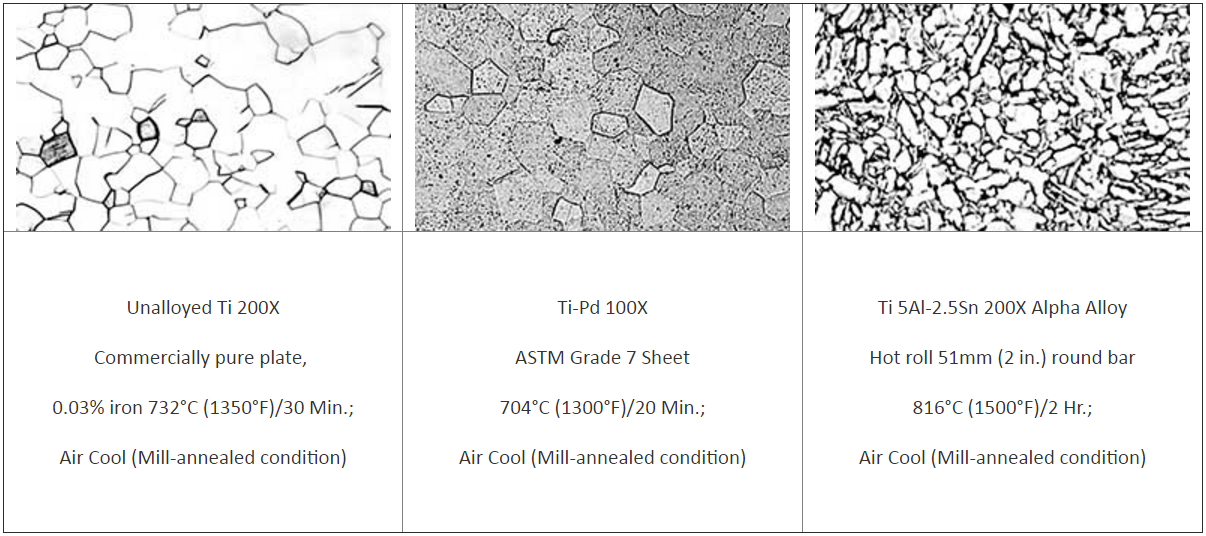

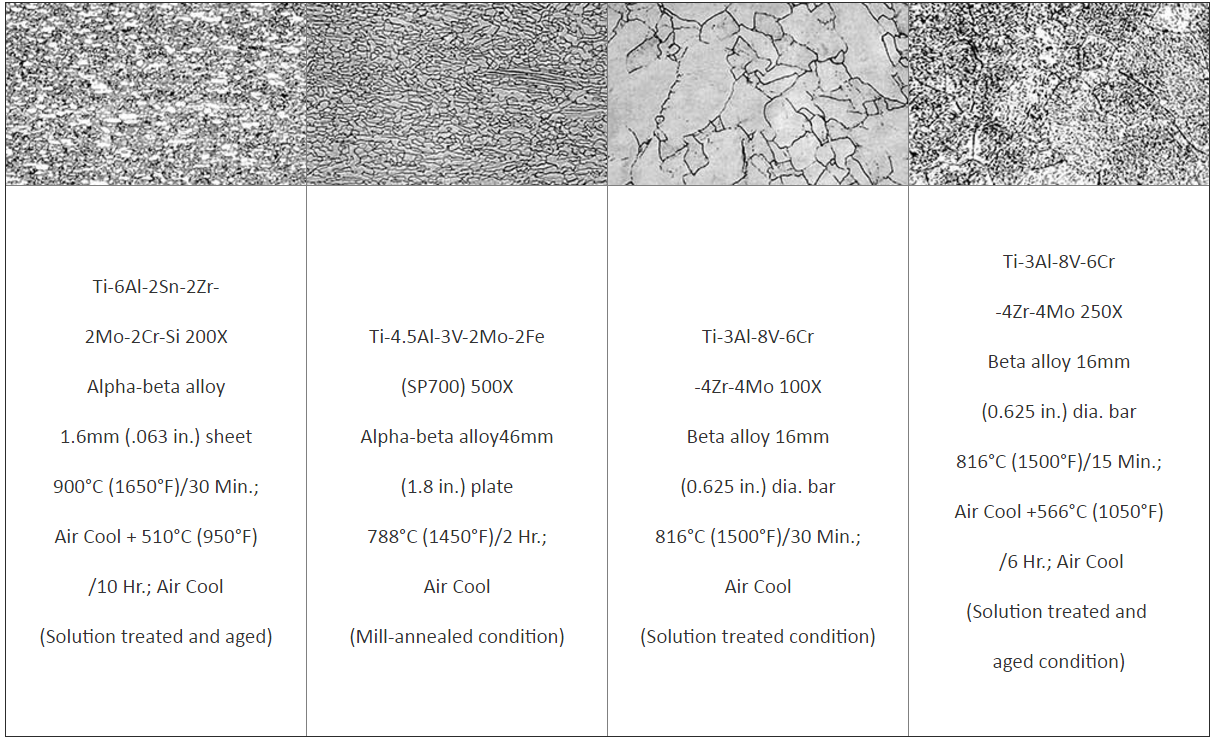

The selective addition of alloying elements to titanium enables a wide range of physical and mechanical properties to be obtained. Basic effects of a number of alloying elements are as follows: Certain alloying additions, notably aluminum and interstitials (O, N,C), tend to stabilize the alpha phase, (i.e., raise the temperature at which the alloy will be transformed completely to the beta phase). This temperature is known as the beta transus temperature. Most alloying additions, such as chromium, niobium, copper, iron, manganese, molybdenum, tantalum, vanadium, stabilize the beta phase by lowering the temperature of transformation (from alpha to beta). Some elements, notably tin and zirconium, behave as neutral solutes in titanium and have little effect on the transformation temperature, acting as strengtheners of the alpha phase. Titanium alloy microstructures are characterized by the various alloy additions and processes. A description of the various types of alloys and typical photomicrographs of various mill products manufactured are illustrated.Alpha Alloys

The single-phase and near single-phase alpha alloys of titanium exhibit good weldability. The generally high aluminum content of this group of alloys assures excellent strength characteristics and oxidation resistance at elevated temperatures (in the range of 316-593°C (600 - 1100°F)). Alpha alloys cannot be heat-treated to develop higher strength since they are single phase Alloys.Alpha-Beta Alloys

The addition of controlled amounts of beta-stabilizing alloying elements causes some beta phase to persist below the beta transus temperature down to room temperature. This results in a two phase system. Even small amounts of beta stabilizers will stabilize the beta phase at room temperature. A group of alloys designed with high amounts of alpha stabilizers and with a small amount of beta stabilizers are alpha beta alloys, usually called high alpha or near alpha alloys. As larger amounts of beta stabilizers are added, a higher percentage of the beta phase is retained at room temperature. Such two-phase titanium alloys can be significantly strengthened by heat treatment thereby quenching from a temperature high in the alpha-beta range followed by an aging cycle at a somewhat lower temperature. The transformation of the beta phase, which would normally occur on slow cooling is suppressed by the quenching. The aging cycle causes the precipitation of fine alpha particles from the metastable beta, imparting a structure that is stronger than the annealed alpha-beta structure.Beta Alloys

The high percentage of beta-stabilizing elements in this group of titanium alloys results in a microstructure that is metastable beta after solution annealing. Extensive strengthening can occur by the precipitation of alpha during aging.