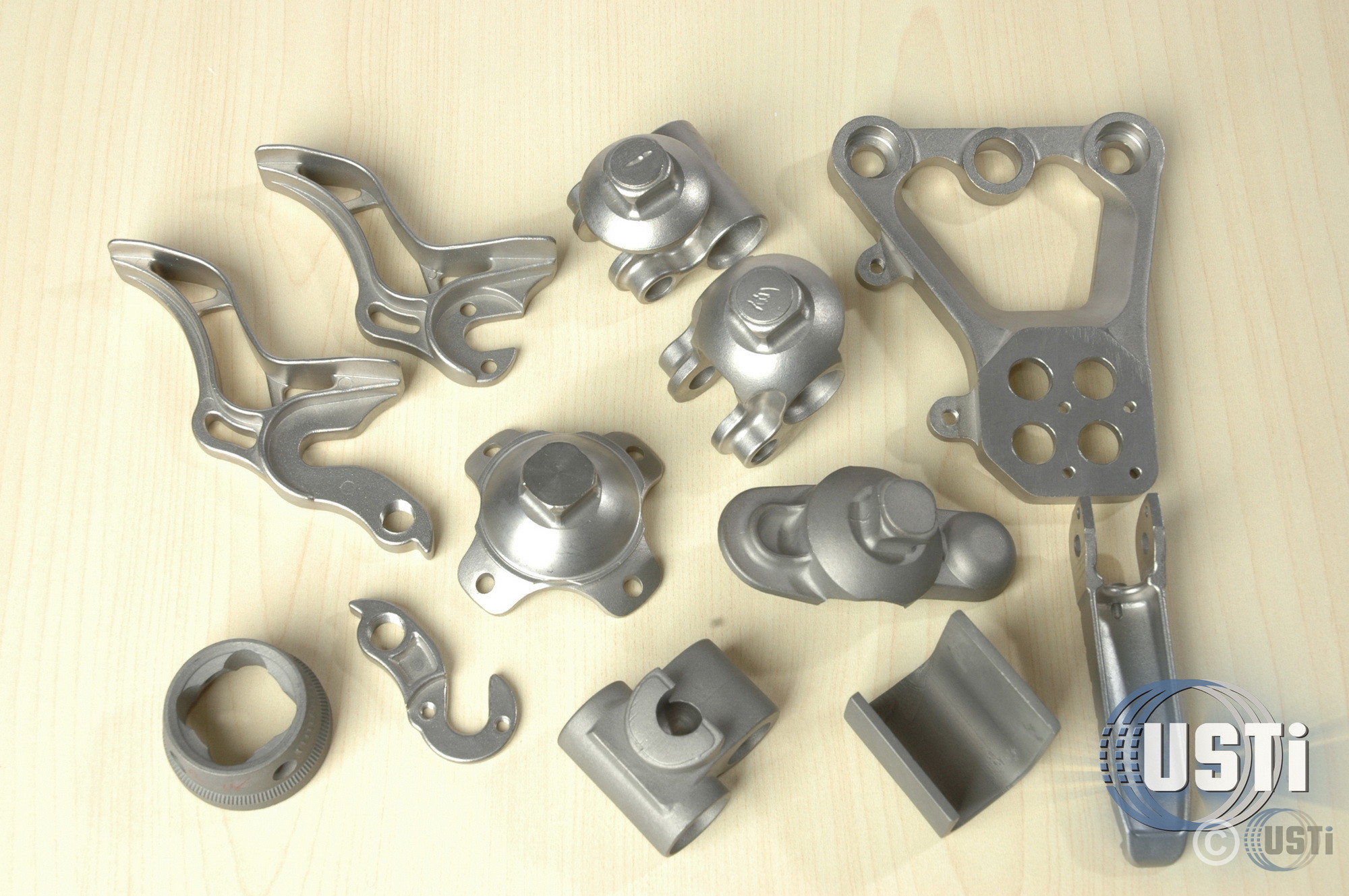

Titanium Casting

Titanium Fastener

September 24, 2016

Medical Titanium

September 25, 2016Material Products

Medical Titanium Products

Titanium Bar/Rod

Titanium Tube / Pipe

Titanium Pipe Fitting

Titanium Clad Steel Plate / Sheet / Tube Sheet

Titanium Plate / Sheet

Titanium Elliptical Head / Spherical Head

Titanium Equipment

Titanium Raw Material

Titanium Forging

Titanium Clad Copper Bar / Tube / Wire

Titanium Wire / Welding Wire

Titanium Machining Part

Titanium Fastener

Titanium Casting

Applications:

Per Customer requirements

|

Apart from the products listed below, other available metal products are not listed here. Other metal products USTi can manufacture and supply include Tantalum, Niobium, Zirconium, Hafnium, Nickel, Copper etc., which are mainly in the form of Plate, Bar and Tube. |

||||

|

Products |

Processing Standard |

Grade |

Size |

|

|

Titanium Casting |

ASME SB367 |

GR2, GR5 (Ti-6Al-4V) |

Min Thickness of Casting: 0.0315” |

|

Technique:

Lost-wax investment casting and lost-foam investment casting are both capable of complicated shapes and small features containing high precision and quality surfaces.Equipment:

Wax injection machines, desiccant rooms, de-wax machines, vacuum melt towers, sinter kiln, and ultrasonic inspection machines.Size:

Per client’s specifications and requirements, from 5g to 30kg.Process:

Wax injecting, slurrying, de-waxing, sintering, casting and furbishing.